Products

-

ASME B16.9 China Supply Pipe End Cap 316/316L Sch40s Stainless Steel Cap in Pipe Fitting

Products Butt weld carbon cap Butt weld Stainless steel cap Size Seamless Pipe Fittings : 1/2″-24″ , DN15-DN600 ERW Pipe Fittings : 24″-72″ , DN600-DN1800. Customize Accepted Thickness SCH10,SCH20,SCH30,STD SCH40, SCH60, XS, SCH80., SCH100, SCH120, SCH140, SCH160, XXS.

Standard ASME B16.9, ASTM A234, ASTM A420, ANSI B16.9/B16.25/B16.28; MSS SP-75 DIN2605-1/2615/2616/2617 JIS B2311 ,2312,2313 EN 10253-1 ,EN 10253-2, etc We can produce as customers’ drawing and standard. Material Carbon Steel ASTM A234WPB,,A234WPC,A420WPL,St37.0,St35.8,St45.8,PG370,PT410,10#,20#,20G,23g,20R,Q235,16Mn, 16MnR,1Cr5Mo, 12CrMo, 12CrMoG, 12Cr1Mo

Alloy Steel A234WP12,A234WP11,A234WP22,A234WP5,A420WPL6,A420WPL3,1.7335,1.7380, 1.0488(1.0566),PA22,PA23,PA24,PA25,PL380

Stainless Steel ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, ect. 1.4301,1.4306,1.4401,1.4571,SUS304,SUS304L,SUS316,SUS316L,SUS321

Surface Treatment Hot Galvanized Black Painting Transparent Oil, Anti-Rust Oil Application Petroleum, chemical, machinery, boiler,electric power, shipbuilding, construction, etc Package Wooden Pallet, Wooden Case, Customers’ Requirement Delivery Within 7-10 days in stock, customized as usual 20 days after receiving advance payment from custoners, also according to quantity

ApplicationLow and middle pressure fluid pipeline, boiler, petroleum and natural gas industry, drilling, chemical industry, electric industry, shipbuilding, fertilizer equipment and pipeline, structure, petrochemical, pharmaceutical industry.

Norminal Pipe Size Outside Diameter at Bevel Length Limiting Wall Thickness For Length E DN Series A Series B E E1 15 21.3 18 25 - - 20 26.9 25 25 - - 25 33.7 32 38 - - 32 42.4 38 38 - - 40 48.3 45 38 - - 50 60.3 57 38 44 5.5 65 76.1 76 38 51 7.0 80 88.9 89 51 64 7.6 500 508.0 529 229 254 12.7 .. .. .. .. .. .. ProductionProduction process:

forming by cold or hot processing methods such as bending, extrusion, pushing, molding, machining, etc.

Application industries:

electric power, oil and gas, petrochemical, chemical, shipbuilding, heating, papermaking, metallurgy, et -

BW Pipe Fitting Elbow

A BW pipe fitting elbow refers to a butt weld (BW) pipe fitting that is shaped in the form of an elbow.

It is used to connect sections of pipe at 90-degree or 45-degree angles, redirecting the flow of fluids or gases.

BW pipe fitting elbows are commonly made of materials such as carbon steel, stainless steel, or alloy steel,

and they are available in various sizes and wall thicknesses to suit different piping systems.

The butt welding connection ensures a strong and leak-free joint.

-

Stainless Steel 304 Weld Neck Flange Custom Carbon Steel Weld Neck Flange

Weld Neck Flange / Butt welding flange refers to a flange with a neck and a round pipe transition and butt welding connection with the pipe. We produce ASME B16.5 butt welding flanges, ASME B16.47 butt welding flanges, DIN 2631 butt welding flanges Welding flanges, DIN 2637 butt welding flanges, DIN 2632 butt welding flanges, DIN 2638 butt welding flanges, DIN 2633 butt welding flanges, etc. Welding flanges are suitable for pipelines with large fluctuations in pressure or temperature or high temperature, High pressure and low temperature pipelines are also used for pipelines that transport expensive, flammable and explosive media. Butt welding flanges are not easily deformed, have good sealing, and are widely used.

Size

Butt welding flange: 3/8″~160″

DN10~DN4000

pressure

American series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

European series: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400

Flange sealing surface type

American series: flat surface (FF), raised surface (RF), grooved surface ( G), Concave and convex surface (MFM), Ring connection surface (RJ)

-

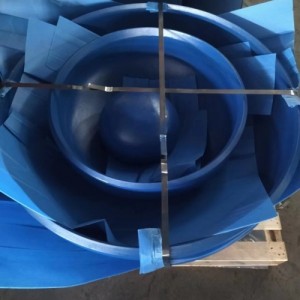

Alloy Steel Pipe Fittings Caps

Alloy steel pipe fittings caps are a type of pipe fitting used to seal the end of a pipe. They are typically made from alloy steel,

which offers high strength and corrosion resistance. Alloy steel pipe fittings caps come in various sizes and end connections to

fit different pipe dimensions and systems. They are commonly used in industrial applications where high pressure and temperature

conditions are present, such as oil and gas, petrochemical, and power generation industries.

-

Seamless Stainless Steel Carbon Steel Reducer Tee Butt Welding Fitting Tee

Seamless Stainless Steel Reducer Tee Butt Welding Fitting Tee

Product DescriptionProducts Butt weld carbon straight tee Carbon steel tee Stainless steel tee Size Seamless Pipe Fittings : 1/2″-24″ , DN15-DN600 ERW Pipe Fittings : 24″-72″ , DN600-DN1800. Customize Accepted Degree 45,90 Thickness Wall Thickness: sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, sch120, sch140 , sch160, xxs, sch5s, sch20s, sch40s, sch80s

Max Wall Thickness: 150mmStandard ASME B16.9, ASTM A234, ASTM A420, ANSI B16.9/B16.25/B16.28; MSS SP-75 DIN2605-1/2615/2616/2617 JIS B2311-2009 JIS B2312-2009 JIS B2313-2009 EN 10253-1 ,EN 10253-2, etc We can produce as customers’ drawing and standard.

GB/T12459-2005 GB/T13401-2005 GB/T10752-2005

SH/T3408-1996 SH/T3409-1996

SY/T0609-2006 SY/T0518-2002 SY/T0518-2002

DL/T695-1999 GD2000 GD87-1101

HG/T21635-1987 HG/T21631-199Material Carbon Steel ASTM A234WPB,,A234WPC,A420WPL,St37.0,St35.8,St45.8,PG370,PT410,10#,20#,20G,23g,20R,Q235,16Mn,

16MnR,1Cr5Mo, 12CrMo, 12CrMoG, 12Cr1MoAlloy Steel A234WP12,A234WP11,A234WP22,A234WP5,A420WPL6,A420WPL3,1.7335,1.7380,

1.0488(1.0566),PA22,PA23,PA24,PA25,PL380

Alloy: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911Stainless Steel ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, ect.,:

1.4301,1.4306,1.4401,1.4571,SUS304,SUS304L,SUS316,SUS316L,SUS321,

Super Duplex Stainless Steel S32750

Stainless Steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N Super Duplex Stainless Steel

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347 -347H

Low Temperature Steel: ASTM/ASME A402 WPL 3-WPL 6

High Performance Steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70Surface Treatment Hot Galvanized Black Painting Transparent Oil, Anti-Rust Oil Application Petroleum, chemical, machinery, boiler,electric power, shipbuilding, construction, etc Package Wooden Pallet, Wooden Case, Customers’ Requirement Delivery Within 7-10 days in stock, customized as usual 20 days after receiving advance payment from custoners, also according to quantity

Payment Term T/T, L/C, D/P ProductionThe tee is a pipe fitting and a pipe connector. The tee is usually used at the branch pipe of the main pipeline. The tee is divided into equal diameter and different diameter, and the ends of the equal diameter tee are all the same size; The size of the main pipe is the same, while the size of the branch pipe is smaller than that of the main pipe. For the use of seamless pipes to manufacture tee, there are currently two commonly used processes: hydraulic bulging and hot pressing. Divided into electric standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

-

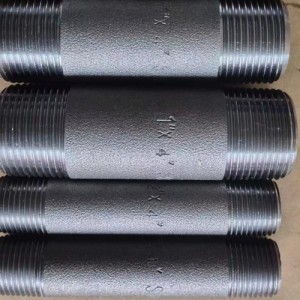

1/2*3 carbon steel pipe nipples

Mild steel pipe nipples are short sections of pipe made from mild steel, typically used to connect other fittings or pipes in plumbing or piping systems.

They are often threaded at both ends to facilitate connections.

Sunny

-

ASME B16.9 Carbon Steel Stainless Steel Pipe Fitting Weld Neck Flange

Butt welding flange/Weld Neck Flange/WN Flange

It refers to a flange with a neck and a round pipe transition and butt welding connection with the pipe. We produce ASME B16.5 butt welding flanges, ASME B16.47 butt welding flanges, DIN 2631 butt welding flanges Welding flanges, DIN 2637 butt welding flanges, DIN 2632 butt welding flanges, DIN 2638 butt welding flanges, DIN 2633 butt welding flanges, etc. Welding flanges are suitable for pipelines with large fluctuations in pressure or temperature or high temperature, High pressure and low temperature pipelines are also used for pipelines that transport expensive, flammable and explosive media. Butt welding flanges are not easily deformed, have good sealing, and are widely used.

Size

Butt welding flange: 3/8″~160″

DN10~DN4000

pressure

American series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

European series: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400

Flange sealing surface type

American series: flat surface (FF), raised surface (RF), grooved surface ( G), Concave and convex surface (MFM), Ring connection surface (RJ) -

Stainless Steel Elbow

A stainless steel elbow is a type of pipe fitting that is used to change the direction of a piping system. It is made of stainless steel,

which provides durability, resistance to corrosion, and the ability to withstand high temperatures. Stainless steel elbows are often

used in industrial and commercial applications where cleanliness and sanitation are important, such as in food processing, pharmaceutical,

and chemical industries. They are also commonly used in plumbing and water treatment systems.

-

Duplex Steel S31803 Reducing Equal Tee

A duplex steel S31803 reducing tee is a type of pipe fitting used to branch a pipe into two different sizes. It is made from duplex stainless steel grade S31803, which offers excellent corrosion resistance and high strength. This type of reducing tee is commonly used in various industries, including oil and gas, petrochemical, and marine applications. It helps in reducing the pipe size while maintaining flow efficiency

-

Pipe Fittings Carbon Steel Flange FL Wn, Lf2, Cl300, Lt, 80, DN20 Flanges, Pipe, Welding Neck Flanges

Flanges of welding neck, socket welding, threaded, blind, slip on, etc.

Butt welding flange/Weld Neck Flange/WN Flange

It refers to a flange with a neck and a round pipe transition and butt welding connection with the pipe. We produce ASME B16.5 butt welding flanges, GOST12820, GOST12821, GOST33259, ASME B16.47 butt welding flanges, DIN 2631 butt welding flanges Welding flanges, DIN 2637 butt welding flanges, DIN 2632 butt welding flanges, DIN 2638 butt welding flanges, DIN 2633 butt welding flanges, etc. Welding flanges are suitable for pipelines with large fluctuations in pressure or temperature or high temperature, High pressure and low temperature pipelines are also used for pipelines that transport expensive, flammable and explosive media. Butt welding flanges are not easily deformed, have good sealing, and are widely used.

Size

Butt welding flange: 3/8″~160″

DN10~DN4000

pressure

American series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

European series: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400

Flange sealing surface type

American series: flat surface (FF), raised surface (RF), grooved surface ( G), Concave and convex surface (MFM), Ring connection surface (RJ)Blind Flange

Blind flanges are made of carbon steel,stainless steel and alloy steel,etc.They are used to seal or block off a pipe, like a cover or cap. We can provide a wide range of blind flanges,in accordance to standards like GOST, ASME B16.5,ASME B16.47,DIN 2634,DIN 2636,and so on.

Size

Blind Flange: 3/8″~100″

DN10~DN2500

Pressure

American Series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

European Series: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400

Flange Facing Types

American Series:Flat Face (FF), Raised Face (RF), Groove (G), Female(F), Ring Joints Face(RJ)Slip On Weld Flange/Flat Welded Flange with Neck

Slip on weld fange can be slid onto a pipe and then welded in place.It is made of carbon steel,alloy steel,and stainless steel.The industrial processes come into die forging,and machining,We can provide a wide range of slip-on weld flanges,following on standards like GOST, ASME B16.5,ASME B16.47,DIN 2634,DIN 2630,JIS,UNI,…and so on.

SIze of slip on weld flange

Slip on weld flange: 3/8″~40″

DN10~DN1000

Pressure

American Series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

European Series: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400

Flange Facing Types

American Series:Flat Face (FF), Groove (G), Ring Joints Face(R)Flat Welded Flange/Plate Flange

These flat welding flanges are GOST, ASME B16.5 flat welding flange, ASME B16.47 flat welding flange, DIN 2634 flat welding flange, DIN 2635 flat welding flange, DIN 2630 flat welding flange, DIN 2636 flat welding method Flanges, DIN 2631 flat welding flanges, DIN 2637 flat welding flanges, etc. Flanges are parts that connect pipes to each other and are connected to pipe ends. There are holes on the flange, and bolts make the two flanges tightly connected. Gaskets are used to seal between flanges. Flat welding flanges are suitable for steel pipe connections with a nominal pressure not exceeding 2.5MPa. The sealing surfaces of flat welding flanges can be made of smooth, concave-convex and tongue-and-groove types.

Size

Flat welding flange: 3/8″~40″

DN10~DN1000

Pressure

American series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

European series: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400 -

Carbon Steel Eccentric Reducer

A carbon steel eccentric reducer is a type of pipe fitting used to connect two pipes of different diameters and is typically

used in piping systems for chemical, petrochemical, and other industrial applications. The eccentric reducer has one side

that is smaller in diameter than the other, and it is designed to prevent air or liquid buildup in the piping system.

Sunny

-

304/316L/304L/904L/321/310 Seamless Stainless Steel Pipe Fitting Tee

304/316L/304L/904L/321/310 Seamless Stainless Steel Pipe Fitting Tee

Product DescriptionWe are a professional tee manufacturer in China, which can provide you with a full range of industrial pipe fittings. At the same time, we also provide industrial pipes, industrial flanges, etc., which conform to ASME B16.9, ISO, API, EN, DIN, BS , JIS, GOST,GB and other standards, are widely used in Russia, Italy, Brazil, Saudi Arabia, Singapore, South Korea, India, Egypt and other countries and regions. If you need such industrial pipe fittings, please contact us.

Products Butt weld carbon straight tee Carbon steel tee Stainless steel pipe fittings tee Size Seamless Pipe Fittings : 1/2″-24″ , DN15-DN600 ERW Pipe Fittings : 24″-72″ , DN600-DN1800. Customize Accepted Degree 45,90 Thickness Wall Thickness: sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, sch120, sch140 , sch160, xxs, sch5s, sch20s, sch40s, sch80s

Max Wall Thickness: 150mmStandard ASME B16.9, ASTM A234, ASTM A420, ANSI B16.9/B16.25/B16.28; MSS SP-75 DIN2605-1/2615/2616/2617 JIS B2311-2009 JIS B2312-2009 JIS B2313-2009 EN 10253-1 ,EN 10253-2, etc GOST standard, etc

We can produce as customers’ drawing and standard.

GB/T12459-2005 GB/T13401-2005 GB/T10752-2005

SH/T3408-1996 SH/T3409-1996

SY/T0609-2006 SY/T0518-2002 SY/T0518-2002

DL/T695-1999 GD2000 GD87-1101

HG/T21635-1987 HG/T21631-199Material Carbon Steel ASTM A234WPB,,A234WPC,A420WPL,St37.0,St35.8,St45.8,PG370,PT410,10#,20#,20G,23g,20R,Q235,16Mn,

16MnR,1Cr5Mo, 12CrMo, 12CrMoG, 12Cr1MoAlloy Steel A234WP12,A234WP11,A234WP22,A234WP5,A420WPL6,A420WPL3,1.7335,1.7380,

1.0488(1.0566),PA22,PA23,PA24,PA25,PL380

Alloy: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911Stainless Steel ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, ect.,:

1.4301,1.4306,1.4401,1.4571,SUS304,SUS304L,SUS316,SUS316L,SUS321,

Super Duplex Stainless Steel S32750

Stainless Steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N Super Duplex Stainless Steel

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347 -347H

Low Temperature Steel: ASTM/ASME A402 WPL 3-WPL 6

High Performance Steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70Surface Treatment Hot Galvanized Black Painting Transparent Oil, Anti-Rust Oil Application Petroleum, chemical, machinery, boiler,electric power, shipbuilding, construction, etc Package Wooden Pallet, Wooden Case, Customers’ Requirement Delivery Within 7-10 days in stock, customized as usual 20 days after receiving advance payment from custoners, also according to quantity

ProductionThe tee is a pipe fitting and a pipe connector. The tee is usually used at the branch pipe of the main pipeline. The tee is divided into equal diameter and different diameter, and the ends of the equal diameter tee are all the same size; The size of the main pipe is the same, while the size of the branch pipe is smaller than that of the main pipe. For the use of seamless pipes to manufacture tee, there are currently two commonly used processes: hydraulic bulging and hot pressing. Divided into electric standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

Packaging & ShippingPackaging:

1. Plywood pallet

2. Plywood case

3. According to customer’s requirements

We could ship by sea, by air, and for small goods we could ship by express.