nipple

-

Galvanized Steel Stainless Steel Pipe Nipples Manufacturer

The threaded joint refers to the pipe connector with thread, is the most common kind of pipe fittings in industry and life, the threaded joint makes the connection of the pipe more simple, disassembly and replacement is also easier, greatly saving the cost of pipe connection.

Application : used for chemical industry , oil ,gas industry etc.

-

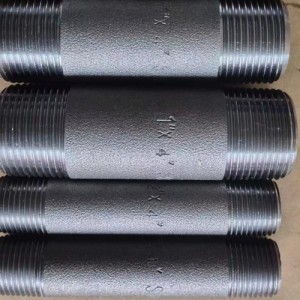

DN6 DN100 Black Steel Pipe Nipples Factory

The threaded joint refers to the pipe connector with thread, is the most common kind of pipe fittings in industry and life, the threaded joint makes the connection of the pipe more simple, disassembly and replacement is also easier, greatly saving the cost of pipe connection.

Application : used for chemical industry , oil ,gas industry etc.

-

Carbon Pipe Fitting Stainless Steel Nipple

A tee has three openings, namely one inlet and two outlet; Or a chemical pipe fitting with two inlet and one outlet, T shape and Y shape, equal diameter pipe mouth, and also reduced diameter pipe mouth, used for three same or different pipe convergence. The main function of the tee is to change the direction of the fluid. Have you enjoyed your vacation in the United States

Application : used for chemical industry , oil ,gas industry etc.

-

Black Steel Welded Seamless Bsp NPT Thread Pipe Nipple

The threaded joint refers to the pipe connector with thread, is the most common kind of pipe fittings in industry and life, the threaded joint makes the connection of the pipe more simple, disassembly and replacement is also easier, greatly saving the cost of pipe connection.

Industrial thread joint is generally made of metal, high pressure resistance, materials are carbon steel, stainless steel, alloy steel, brass, etc.

Black pipe nipple is made of carbon steel pipe, and face is black, thread standard is ASTM

-

Stainless Steel Pipe Connector Threaded Pipe Nipples

The threaded joint refers to the pipe connector with thread, is the most common kind of pipe fittings in industry and life, the threaded joint makes the connection of the pipe more simple, disassembly and replacement is also easier, greatly saving the cost of pipe connection.

-

NPT Thread Pipe Nipple Black Steel

Hebei Cangrun Pipeline Co., Ltd. is a manufacturer specializing in the production of stainless steel tube fittings and pipe fittings. The short pipe outer wire – double end outer wire products produced by us have the characteristics of light pipe weight, simple welding process, convenient construction and low comprehensive engineering cost. Under the condition of rated temperature and pressure, the pipe can be used safely for more than 50 years. The whole process is in accordance with the national IS09001 quality certification standard design and production, in the use of our customers, has obtained a high reputation of reliable quality and excellent service.

Application : used for chemical industry , oil ,gas industry etc.

.

-

High Quality Carbon Steel Galvanized Threaded Nipple

This Grainger Approved nipple has a weld bead on the inside and is NPT threaded at both ends. Model is interchangeable with galvanized cast iron or steel and is suitable for low-pressure plumbing applications including air, water, oil, natural gas, and steam. Certified for use in potable water applications.

Application : used for chemical industry , oil ,gas industry etc. -

Hot DIP Galvanized Pipe Nipple OEM ODM

The nipple is mainly used for matching hardware fittings, such as can be installed in various pipe interfaces. The wire is made of high quality zinc alloy material, the color is silver.

-

NPT Black Steel Carbon Steel Pipe Nipples

Black steel pipe nipples are short sections of black steel pipe that have threaded ends,

allowing them to be easily connected to other pipes or fittings.

They are commonly used in plumbing and gas applications,

as well as in industrial settings. Black steel pipe nipples are durable and resistant to corrosion,

making them suitable for a variety of environments. They are available

in different sizes and lengths to accommodate specific needs and requirements.

-

1/2*3 carbon steel pipe nipples

Mild steel pipe nipples are short sections of pipe made from mild steel, typically used to connect other fittings or pipes in plumbing or piping systems.

They are often threaded at both ends to facilitate connections.

Sunny

-

Carbon Steel Stainless Steel Pipe Nipple

A pipe nipple is a short piece of pipe with threads on both ends that is used to connect two other fittings or pipes.

Pipe nipples come in various materials, sizes, and lengths, and they are used in plumbing and industrial applications to

allow for connections between pipes or to change the direction of fluid flow.

Comparison between carbon steel and stainless steel pipe nipples:

Carbon Steel Pipe Nipple

Material: Made from carbon steel, which is an alloy of iron and carbon.

Durability: Strong and durable, but can corrode if not protected or if used in corrosive environments.

Cost: Generally less expensive than stainless steel.

Applications: Commonly used in non-corrosive environments or where the material is protected from corrosion

(e.g., painted or coated). Suitable for conveying gas, water, oil, and steam.

Stainless Steel Pipe Nipple

Material: Made from stainless steel, which is an alloy of iron, carbon, and a minimum of 10.5% chromium.

Corrosion Resistance: Highly resistant to corrosion, making it suitable for use in corrosive environments.

Cost: More expensive than carbon steel due to its higher resistance to corrosion and other beneficial properties.

Applications: Ideal for applications that require resistance to corrosion and heat. Commonly used in chemical plants,

food processing facilities, and marine applications.

Key Differences

Corrosion Resistance: Stainless steel offers superior corrosion resistance compared to carbon steel.

Cost: Carbon steel is generally more cost-effective for non-corrosive applications.

Application Environment: Stainless steel is preferred in environments that are acidic, alkaline,

or otherwise corrosive, while carbon steel is suitable for less demanding conditions.

-

Steel Pipe Nipple

Product Name: Steel Pipe Nipple

Size: 1/8″-6″

Thickness: SCH5S-SCH160